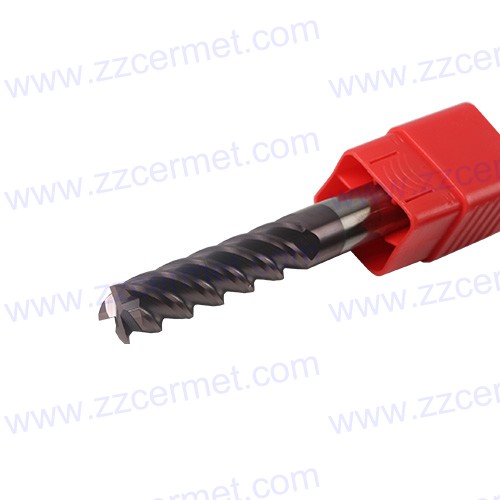

HRC55°4 flutes flattened end mills for all kind of materials

Type:HRC 55°4 flutes flattened end mill

Material:Tungsten carbide

Hardness:HRC≤55°

Coating:TiAlCrN

4 Flutes flattened end mills for general cutting all kinds of materials

| Flutes No. | 2/4 Flutes |

| Material | Tungsten carbide |

| Coating | TiAlCrN |

| Helix Angle | 35° |

| Hardness | HRC55° |

| Customized | Accept |

| Smooth Finish | Highly polished |

| Feature | Excellent chip evacuation |

| Measurement | Metric |

Technology&Application

Incorporate latest molding, coating, edge preparation,and other manufacturing technology. Provide superior performance.

Coatings provide high-speed capability and are engineered from finishing to heavy roughing,The post-coat treatment reduces coating stresses, improves coating adhesion, minimises microchipping and edge build-up, and improves workpiece finish.Coated surface enable to get Longer tools life.

Application areas: Machining of cast iron, nonferrous alloy, chill cast iron, hard steel, stainless steel, plastic materials, fiberglass, carbon fiber and other non-metallic.

Served industries: Aerospace,Transportation,Medical Equipment,Military Manufacturing,Mold Development,etc.

| Item No.: | Edge diameter | Edge length | Overall length | Shank diameter |

| BL4F*1*3*50S4 | 1 | 3 | 50 | 4 |

|

BL4F*1.5*4*50S4 | 1.5 | 4 | 50 | 4 |

|

BL4F*2*6*50S4 | 2 | 6 | 50 | 4 |

|

BL4F*2.5*8*50S4 | 2.5 | 8 | 50 | 4 |

|

BL4F*3*8*50S4 | 3 | 8 | 50 | 4 |

|

BL4F*3.5*10*50S4 | 3.5 | 10 | 50 | 4 |

|

BL4F*4*10*50S4 | 4 | 10 | 50 | 4 |

|

BL4F*5*13*50S6 | 5 | 13 | 50 | 6 |

|

BL4F*6*15*50 | 6 | 15 | 50 | 6 |

|

BL4F*7*20*60 | 7 | 20 | 60 | 8 |

|

BL4F*8*20*60 | 8 | 20 | 60 | 8 |

|

BL4F*9*25*75 | 9 | 25 | 75 | 10 |

|

BL4F*10*25*75 | 10 | 25 | 75 | 10 |

|

BL4F*11*30*75 | 11 | 30 | 75 | 12 |

|

BL4F*12*30*75 | 12 | 30 | 75 | 12 |

|

BL4F*14*35*80 | 14 | 35 | 80 | 14 |

|

BL4F*16*40*100 | 16 | 40 | 100 | 16 |

|

BL4F*18*40*100 | 18 | 40 | 100 | 18 |

|

BL4F*20*40*100 | 20 | 40 | 100 | 20 |

Service We Can Offer You:

♣Quick Response:Your inquiry will be replied within 24 hours.

♣High Quality:Well-trained workers and more than 10 years experience.

♣Competitive Price:Directly from factory to save your money.

♣Short Lead Time:Being efficient:3-7 days for samples and 10-35 days for quantity orders.

♣Flexibility:Small orders are acceptable for quick delivery and to help you reduce stock cost.

♣OEM:Custom fabrication according to your drawings ,samples or designs.

Carbide inserts

Milling inserts

Carbide cutting tools

Carbide endmill

End mill

Carbide end mill

Solid Carbide cutting tools

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Doris

E-mail: info@zzcermet.com

Add: No.1 of Longxin international building, No.255 of Tongxia Road,Shi Feng District, Zhuzhou Hunan Province,China